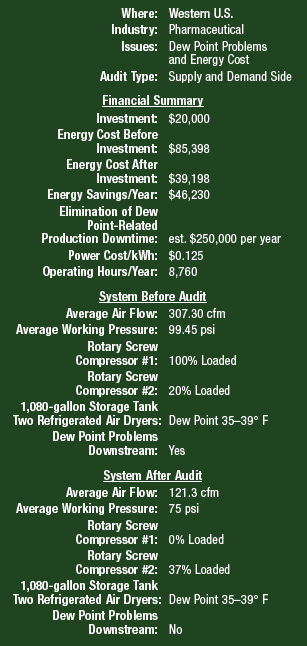

A. Introduction

This West Coast

pharmaceutical facility has a very clean and organized compressed air

system. All equipments is in good working order in the compressor room.

The compressor room itself is very clean and well ventilated. The

management requested a compressed air system audit for two reasons:

- Production problems and downtime resulting from the presence of moisture in the compressed air lines. The compressor room dryers were functioning properly so how could this happen?

- Awareness of the high cost of compressed air and a desire to find ways to reduce compressed air demand.

This article will

describe the actions taken to address these two issues. The facility

operates “24/7” so we have 8,760 operational hours per year. The

average electrical rate at this facility is $0.12 kW/h. The power cost

formula used is based upon the facility’s current operating conditions

of 3.89 CFM/BHP and 95% average motor efficiency.

Power Cost = (BHP *0.746 * 8,760 hours x $0.12 per kW/h) / Avg. Motor Efficiency (95%)

The focus of this audit is on the “Demand

Side” with the very top priority being to identify the root cause of the

presence of moisture in the compressed air lines.

B. Compressor Room Review

The Compressor Room is extremely clean and

well ventilated. There are two rotary screw compressors which are oil

lubricated and air-cooled. The air is dried by two parallel

refrigerated air dryers. The air then goes into a common header and

flows into a 1,040 gallon air storage tank. The air then flows into a

Intermediate Flow Controller. From here the compressed air leaves the

compressor room and enters the facility. The average CFM per BHP

between the two air compressors is 3.80 CFM per BHP.

Upon entering the compressor room we noted

an audible air leak in Compressor #2. We found the leak to be coming

from the air end and recommended that the air compressor service

provider be contacted immediately. Both air compressors are operating

via modulation control. Compressor #2 acts as the base load machine

while Compressor #1 is the back-up machine when pressure falls to a

predetermined set point.

The two refrigerated air dryers are in good

working condition and functioning properly. They are designed to

produce a dewpoint range between 33 F and 39 F at a maximum flow of 330

CFM at 100 psi. We took dewpoint measurements at the compressor room

outlet (for one week) and found that the average dewpoint achieved was

36 F. This correct dryer performance is what has the facility

bewildered by the presence of water in the compressed air lines in the

factory. It is worth noting that the dryers are not capable of drying

the full air output capacity of the air compressors if factory demand

should increase. The dryers have integrated 1 micron particulate

filters. We recommend that the facility install a 0.01 ppm oil

coalescing filter to protect against oil contamination downstream.

The 1040 gallon air storage tank is

adequate for the air demand in the facility. During production we

recorded an average air flow of 307.30 CFM which means the tank is

providing 3.38 gallons of storage per 1 CFM of air storage. The tank is

also piped properly (after the air dryer) with air entering the bottom

of the tank and exiting the top – providing more surface area for

moisture to be separated and fall to the bottom of the tank.

C. Solving the Problems with Moisture

It was initially reported that the plant

was “having problems resulting from an excess of water in the compressed

airlines”, with the primary area of concern being the small cylinders

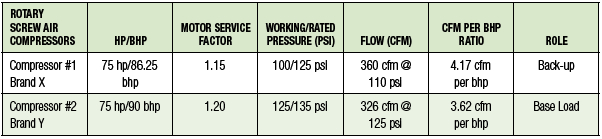

in the plant. As a standard part of our audit procedure we took dewpoint

readings. These test showed a refrigerated drying system according to

its specifications. The data depicted below shows a very steady

dewpoint with less than half a degree fluctuation over a ten minute time

span. The 36 °F average dewpoint is well within the expected range of

performance for these dryers.

As a result of the ongoing condensation

issues, the factory had taken some actions in hopes of remediating the

problem. The solution the plant put into place was to install water

separators on each line and open the drains on

Filter-Regulator-Lubricators (FRL’s) throughout the plant. We found a

total of 18 FRL units with the drains open, exhausting approximately 2

CFM each worth of compressed air, totaling 36 CFM worth

of compressed air. The problem with this is that the only thing

exhausting through the drains was compressed air, thereby decreasing

plant pressure at the same time.

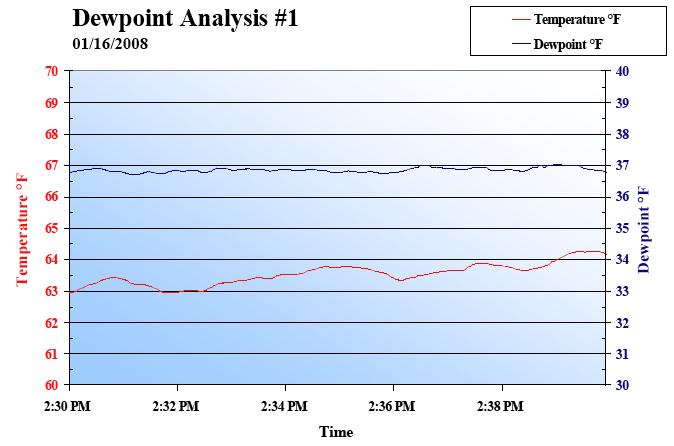

Moisture in Pneumatic Cylinders Created Production Down-Time

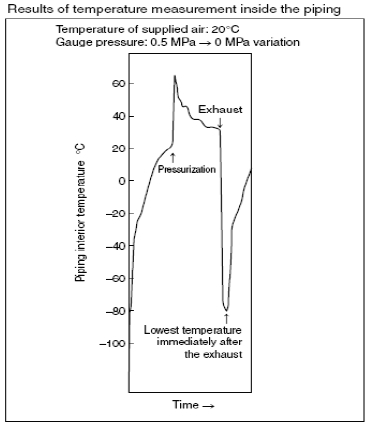

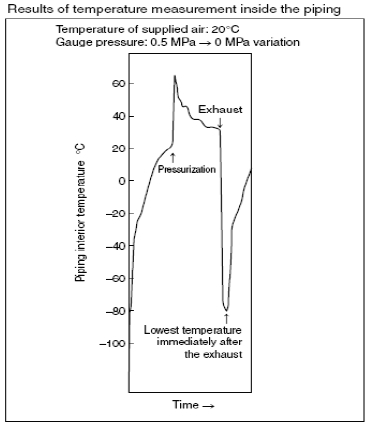

Adiabatic Expansion

Through further invest igation

we found the root of the problem. When air is discharged from the

piping between the cylinder and the valve, the temperature of the air

drops due to adiabatic expansion. . If the atmospheric dewpoint of

the supply air is T1, and the temperature of the air T2 after adiabatic

expansion falls below this value (T1

igation

we found the root of the problem. When air is discharged from the

piping between the cylinder and the valve, the temperature of the air

drops due to adiabatic expansion. . If the atmospheric dewpoint of

the supply air is T1, and the temperature of the air T2 after adiabatic

expansion falls below this value (T1

igation

we found the root of the problem. When air is discharged from the

piping between the cylinder and the valve, the temperature of the air

drops due to adiabatic expansion. . If the atmospheric dewpoint of

the supply air is T1, and the temperature of the air T2 after adiabatic

expansion falls below this value (T1

igation

we found the root of the problem. When air is discharged from the

piping between the cylinder and the valve, the temperature of the air

drops due to adiabatic expansion. . If the atmospheric dewpoint of

the supply air is T1, and the temperature of the air T2 after adiabatic

expansion falls below this value (T1

The Solution to Moisture Problems in Pneumatic Cylinders

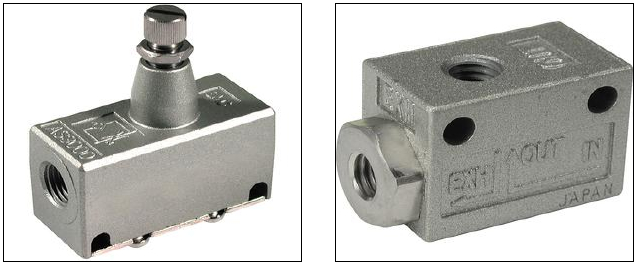

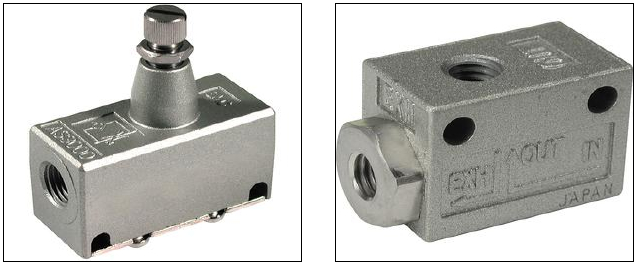

There is a very effective solution to this

problem, the installation of quick-exhaust valves directly onto the

cylinders. These will allow for the cylinder to fully exhaust on every

cycle, thereby eliminating condensation build up and save the cylinders.

Along with saving the cylinders in the plant, there is no need to keep

the drains of the FRL’s opened in the plant. Leaving the drains opened

is actually creating a larger pressure drop throughout the plant, and

wasting 36 CFM of compressed air.

Understanding what is happening with the

pneumatic cylinders was the key to solving this problem. The facility

had been considering installing desiccant air dryers. This would have

been a significant capital expense and would not have solved the

problem. We were able to identify the adiabatic expansion occurring

between the cylinder and the valve. The solution deployed of

quick-exhaust valve was a minor expense and achieved with little effort.

Quick Exhaust Valves Solved the Problems with Moisture

D. Demand Side Audit

Aside from solving the downstream moisture

problem, our audit reviewed pneumatic circuitry in the facility and also

included a compressed air leak audit. Below is a brief summary of some

of the opportunities discovered and solved. The end result was that

air demand was reduced by 186 CFM. This reduced the plant compressed

air demand from an average of 307 CFM to an average of 121 CFM.

The Five Label-Aire Machines

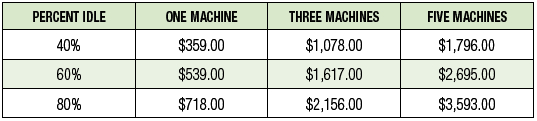

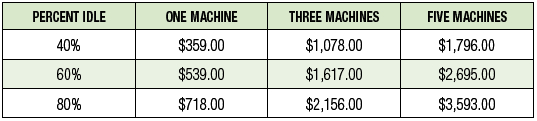

We took note of five Label-Aire machines in

the factory. These units were constantly being pressurized even when

not being used. We conducted a point-of-use test on these machines and

found that each machine consumed an average of 4.2 CFM even when not in

use. We only sampled a fragment of time so we are not sure of what

percentage of the time the machines are idled but plant personnel tell

us that it is a significant percentage of time.

The solution here is to keep the Label-Aire

machines from consuming air when idled. This is easily achieved by the

installation of two-positioned solenoid valves. The

solenoid of these valves will effectively actuate this application only

when the product is present. The solenoid of these two-positioned valves

can be actuated via several applications such as relay sensors and

electronic signals. The table below shows the savings opportunity.

Label-Aire Machines Air Consumption Costs When Idle

The Ten Blow Guns

There are ten blow guns at the facility

which use inefficient nozzles. This can be costly in the long run due

to the decreased impact pressure and increased waste of compressed air.

We recommend using high-efficiency nozzles, which can reduce air

consumption by 50-75% while increasing the impact pressure at the work

surface. These high-efficiency nozzles utilize the Venturi effect to

gain efficiencies.

High Efficiency Nozzles on Blow Guns

The Cutter Machine Causes Plant Over-pressurization

The cutter machine is causing the entire

plant to run at 100 psig because it requires 95 psig. We conducted a

point-of-use test on this machine to verify its’ air usage. The machine

was operating between 85 and 90 psig when we started the test. Actual

pressure changed over time from 71 psig to 104 psig with 90 being the

average. Air flow went from 20 cfm to 10.4 cfm with 4.3 cfm being the

average. The cutter was actuating twice a minute, in one minute and 15

second cycles with an intermitten down period of approximately two and

one-half minutes.

Due to the intermittent demand of this

application, we are recommending the use of a pneumatic booster coupled

with a air receiver. This will allow us to reduce the air pressure

across the entire facility.

Air Leaks

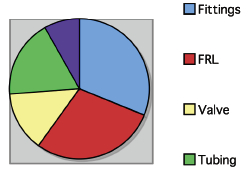

|

Leak locations in % at the facility |

We have identified and tagged 28 compressed

air leaks in the facility. They account for 120 CFM equating to 39% of

the plants’ average air flow of 307 CFM. Leaks were found on the

airend of one air compressor, and plant-wide on FRL’s, fittings, gauges,

and pneumatic tubing.

It is important to have a leak remediation

campaign in place to keep leaks from consuming unnecessary compressed

air. A proactive approach to leak detection should include all

individuals within the plant and the education of machine operators on

the cost of leaks.

Machine operators could then combat leaks

as they develop by immediately tagging them and notifying maintenance.

This approach to leak remediation is perfect for leaks that can be

easily felt and heard. Some leaks cannot, unfortunately, be detected by

the human ear. We utilize ultrasonic leak detectors to find leaks that

are out of range and hard to hear or feel.

E. Capture the Savings

Air Leak on FRL |

Multiple Holes/Leaks in Tubing |

|

|

Air Leak on Hose/Fitting Connect |

The demand side audit made it possible for

us to reduce average air demand from 307 CFM to 121 CFM. We fixed leaks

(120 cfm), closed open drain valves (36 cfm), and will reduce over-all

plant pressure (30 cfm). We now need to look at how the compressors are

operating and if they controls are set to capitalize on the new

compressed air demand profile.

The “Before” situation was this to produce 307.3 cfm:

- Compressor #1 ran 100% loaded in modulation mode. At 100% power it had 90 BHP which equated to $74,292 in annual costs of operation.

- Compressor #2 ran 20% loaded in modulation mode. At 78% of power it consumed 67.3 BHP equating to $11,106 in annual energy costs of operation.

- Total annual energy cost of operation was $85,398

The “After” situation was this to produce 121.3 cfm:

- Compressor #1 was placed on standby for emergency situations. $0 energy cost.

- Compressor #2 was capable of having its’ controls modified to Load/No-Load. We ran the machine 37% loaded to meet the demand. At 55% of Power it had 47.45 BHP equating to $39,168 in annual energy costs of operation.

- Total new annual energy cost of operation was $39,168

The new annual energy costs to run the air compressors represents a savings of $46,230 per year.

Conclusion

Understanding pneumatics is core to

conducting a strong demand side audit. Pneumatic circuits were where

the audit was able to discover the dewpoint problem and the

opportunities to reduce air consumption and pressure. Understanding air

compressors and air compressor controls then allowed the installations’

energy costs to be reduced as a result of the demand side improvements.

No comments:

Post a Comment